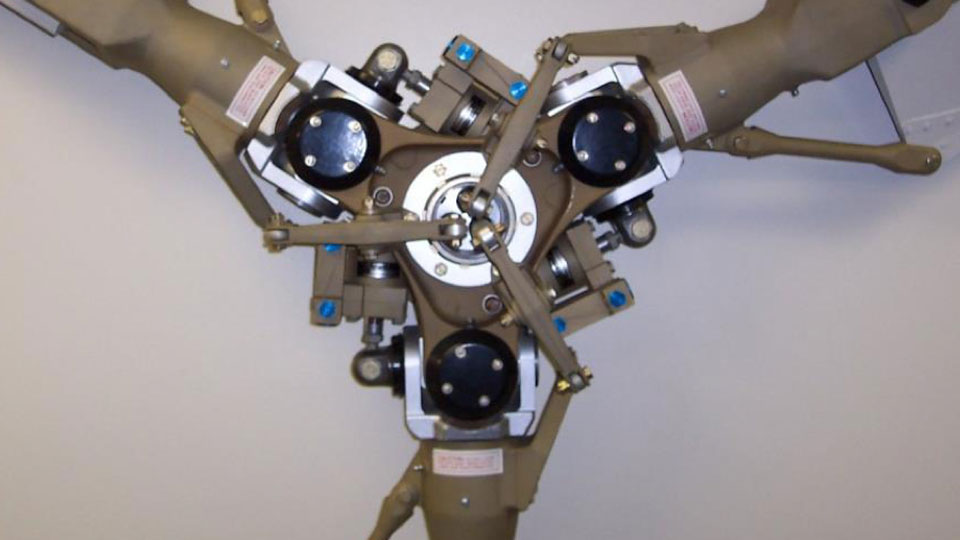

Rotor with three articulated blades 280FX

A UNIQUE ENGINEERING

THREE BLADES ARTICULATED ROTOR SYSTEM

The main rotor on the 280FX is a three bladed high inertia system, fully articulated, which has accumulated four millions flying hours with excellent statistics and without any catastrophic failure. During autorotations, the great inertia of this rotor system generates much better performances than other light helicopters. That three bladed system has a much lower disc load which allows faster recovery in case of an eventual power loss. A three blades rotor system has also better performances in case of maneuvers under negative G or during operations with heavy loads, or at high altitude, in case of heavy gusts or at high speed.

Furthermore the three bladed rotor is not subject to any mast bumping which is common to all other two blades helicopters.

It allows also landings in unprepared terrain with up to 15° slope. This gives much more flexibility to flying instructors to choose their training site.

Recent Comments